Packaging for electronics is critical for protecting components and used often for objects that are delicate and easily damaged. Various packaging films are used extensively in electronics and electronic packaging to facilitate signal transmission, heat dissipation, electromagnetic interference shielding, as well as to provide protection from moisture, chemicals, radiation, and other forms of contamination.

A variety of films and materials exist to serve varying functions in electronics packaging, based on their electrical resistivity:

- Conductive films

- Electrostatic dissipative (ESD) films

- Antistatic films

- Insulative films

Measuring Resistance of Films

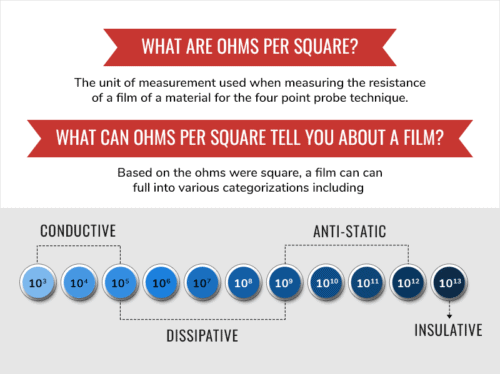

When working with any kind of film, measuring its resistance through the four-point probe technique can help shed light on the film’s effectiveness or capabilities. Ohms per square is the unit of measurement associated with resistance, and below is a visualization of what that measurement says about a film:

Ohms per Square

Conductive Films

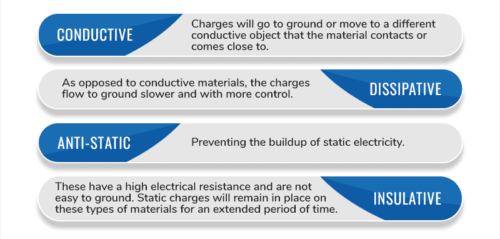

Conductive films allow electric charges to transfer electric charges to other conductors or to ground to negate static buildup. Featuring both electrical conductivity and optical transparency, these films are used in a variety of electronic equipment.

ESD Films

ESD films slow the movement of electric charges, allowing them to safely dissipate in a more controlled manner than conductive films. Electrostatic dissipative film is used as protection for sensitive equipment and components. It prevents discharge from human contact.

Anti-static Films

Antistatic films are used to inhibit the buildup of static electricity. They allow static charge to decay at a very slow rate.

Insulative Films

Unmodified plastics are generally insulative and do not allow electric charges to flow freely through them. Insulative films often act as a barrier for sealing goods to prevent quality degradation and preserve the original condition of the package contents. They function as a protective layer from environmental elements often in the food and electronic industry.

Working with Integrated Packaging Films

Integrated Packaging Films (IPF) is a pioneer in the development and implementation of ESD packaging using recycled PET. We offer ESD properties in both a washable and non-washable form to suit our customers’ needs and budgets. We provide a variety of thermoformable antistatic, ESD, and conductive films. We offer films made from a variety of materials, including:

- Amorphous polyethylene terephthalate (APET)

- Recycled polyethylene terephthalate (RPET)

- Polyethylene terephthalate glycol-modified (PETG)

- High impact polystyrene (HIPS)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

We offer all films in custom-slit widths and thicknesses ranging from 0.01–0.05 inches. We custom-extrude APET, RPET, PETG, and PP materials to meet the unique demands of any application. Our materials meet or exceed all ESD/EOS and Mil-Spec compliance standards for surface resistivity and static decay. Our value-added 100% recyclable packaging is commonly used by leading manufacturers in the medical, electronics, general purpose, and food and beverage industries.

Why Choose IPF Electronic Packaging Films?

At IPF, we pride ourselves on providing high-end packaging materials, superior customer service, and quick turnaround times for our customers regardless of order volume. Our lower MOQs (excluding color-matched orders) are possible due to our capacity to run smaller quantities on specialty films. We work to provide solutions for all budgets and delivery requirements, and we can often provide orders faster and cheaper than many of our competitors.

Please contact us or request a quote for more information about the electronics packaging film solutions available from Integrated Packaging Films.