bio-based

bio-based

wide assortment

wide assortment

made locally

made locally

easy and affordable

easy and affordable

Food Packaging:

In the world of food packaging, it’s all about looks. And operational efficiency, of course!

We’ve been thermoforming plastic sheets to make FDA and CFIA compliant plant-based clamshells, blisters and trays since 2006, so we understand the importance of keeping your rollstock crystal clear and sanitary.

Whether you need certified compostable, curbside recyclable with PCR resin (post-consumer recycled plastic), we can mix up a custom bio-based blend and deliver a clear thermoform plastic sheet.

With awesome clarity on its own or in an array of eco-friendly tints to meet your requirements, our bioplastic rollstock can also include specialized anti-fog coating, internal anti-block and de-nesting enhancements to ensure your thermoformed food packaging looks oh-so pretty and your shop floor runs smoothly. 🌿

Packaging for Electronics:

We blend ESD coatings and sustainability into a bioplastic sheet to keep your gear free from zaps. ⚡️

Static electricity, external damage, and did we mention static electricity? As recognized industry leaders in ESD and controlled conductivity for charge dissipation, we now combine bio-based materials with our specialty ESD expertise to make you a precision extruded plastic sheet that keeps your gear grounded AND gives the planet a big high-five.

We can deliver sheets with surface resistivity of 10⁷ to 10¹⁰ ohm per square for the containment, transport and long-term storage of microchips, printed circuit boards and other ESD-sensitive components. Bring us your specs and let us show you what’s possible with today’s bioplastics!

Pharmaceutical Packaging:

Bio-based options for healthcare applications, from medical equipment to protective shields.

We're authorized to supply certified bio-based rigid and co-extruded rigid rollstock that complies with FDA standards for the packaging of sensitive medical components such as catheters and syringes and is compatible with form, fill, and seal processes.

With robust barrier properties that maintain ESD integrity even when wet, your packaging will retain excellent clarity for reliable barcode scanning and preservation of sanitation, even when blended with recycled resin. ♻️

Packaging for Retail:

Bioplastic utility packaging with tough guy durability for high exposure retail environments. 💪

Our deep expertise in bio-based resins allows us to be competitive in the general utility packaging market. We offer crystal clear transparency in a high gloss, bioplastic sheet for thermoforming trays, tubs, and on shelf display and fixturing components.

Our rigid rollstock can be shaped and die cut for multiple applications, including hang tags and inserts. All our bioplastics carry certificates of compliance, and we can offer tracking of raw materials to support ISO requirements where required.

Value Added Services

tolling

Drowning in excess flake or resin? Toll converting is our thing and great for the planet! Bring us your weary scrap and regrind. We'll recycle it into new material for us and savings for you.

grinding

Not even at the flake stage yet? Don't stress - we're up for a little grinding. The more material we all find ways to re-use, the better, so let us help turn your scrap mountain into a molehill!

slitting

Worried about waste if standard rolls don't fit your machine? Our precision rigid film slitting lets you order off the regular menu and cut down to size. Or try our buyback tolling or grinding services.

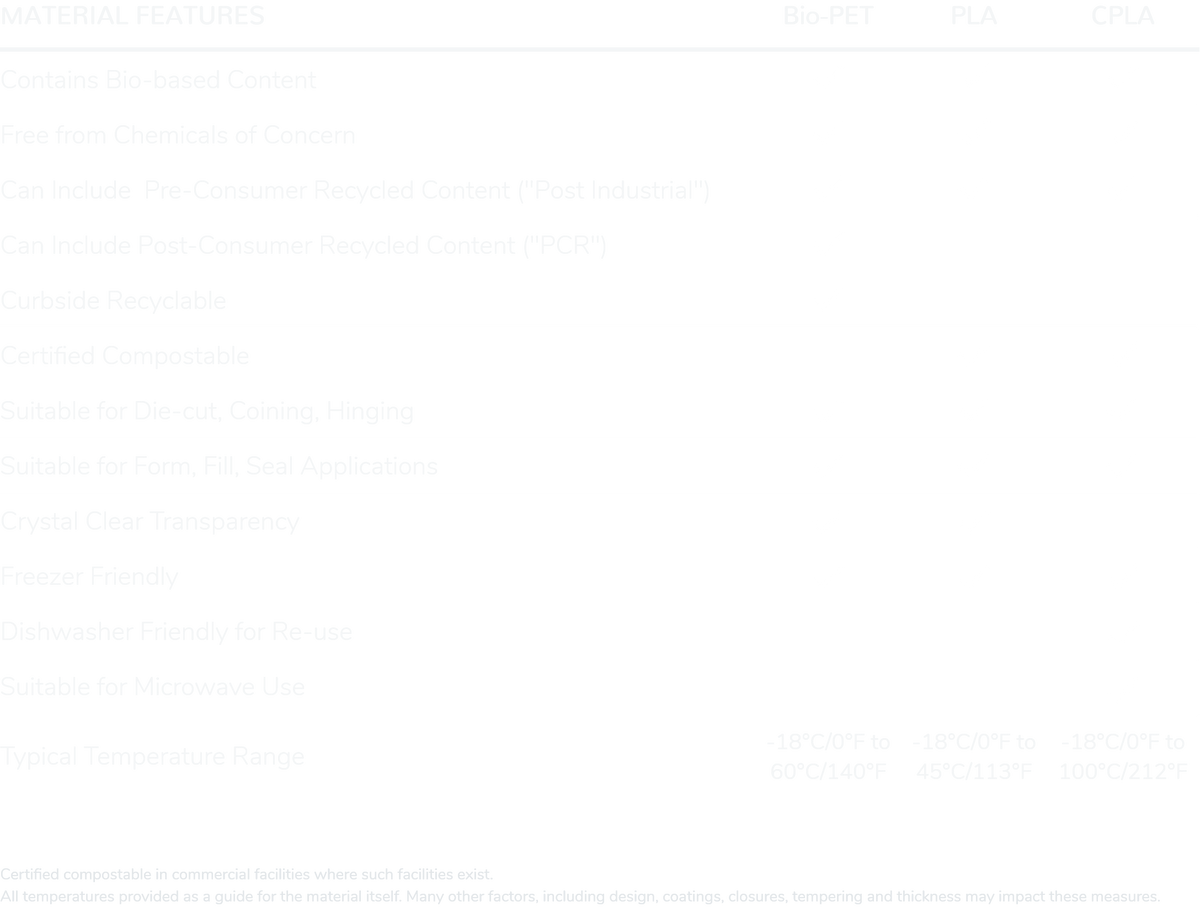

Certified Compostable PLA Rollstock

Made from up to 99% plant-based materials, and no BPAs, phthalates or other nasty stuff, we can get you on your way to eliminating fossil fuels from your thermoformed packaging in no time. Our PLA rigid rollstock works with standard molds & equipment with minimal adjustments. So if you’ve got the mold and just need the roll, let us show you just how easy the switch to plant-based can be.

The Workhorse

TFF02000 –– 99% plant-based, food safe and heat resistant to 113°F (45°C), these sheets are great for food applications where high heat is not an issue and are BPI certified compostable up to a gauge of 0.040" (40mil).

The Step Up

TFF02005 –– 99% plant-based, food safe and heat resistant to 113°F (45°C), it’s got some extra oomph for a bit more drop-kick durability and is BPI certified compostable up to a gauge of 0.040" (40mil).

The Hot Stuff

TFF06000 –– Suitable for microwave heating, this 97% plant-based, translucent sheet can withstand temperatures up to 212°F (100°C) and is BPI certified compostable up to a gauge of 0.026" (26mil).

Curbside Recyclable

Bio-PET Rollstock

Hot off the press, we’re one of the only Bio PET sheet extruders and thermoformed packaging producers in North America! Our rollstock processes, forms and performs identical to traditional PET, because well, it is PET. The only thing different is it’s made with up to 30% renewable, bio-based content instead of fossil fuels.

Bio-PET is fully curbside recyclable along with traditional PET #1, meaning our Bio-PET rollstock can also contain up to 25% post-consumer recycled resin (PCR) or 33% rPET while maintaining a minimum of 20% bio-based content. 🎉

The Clear Winner

BPF00002 –– all virgin material made from 30% bio-based content, it has awesome clarity and is suitable for both food and medical applications.

The Hybrid

BPF00003 –– food safe formulation made with 20% bio-based content and a minimum 33% pre-consumer recycled material.

The Identical Twin

BPF00005 –– made with 30% bio-based content and up to 50% pre-consumer recycled Bio-PET for a double dose of renewable materials that’s also approved for food use.

The Full Circle

BPF00030 –– food safe formulation made with 20% bio-based content and 25% post-consumer recycled resin (PCR). How’s that for a 1-2 punch?